Welcome, fellow small manufacturers! Are you looking to take your business to the next level and maximize efficiency? Look no further than ERP solutions. These powerful tools can streamline your operations, improve communication, and boost productivity. In this article, we will explore how ERP solutions can revolutionize your small manufacturing business and help you achieve your goals.

Importance of ERP for Small Manufacturers

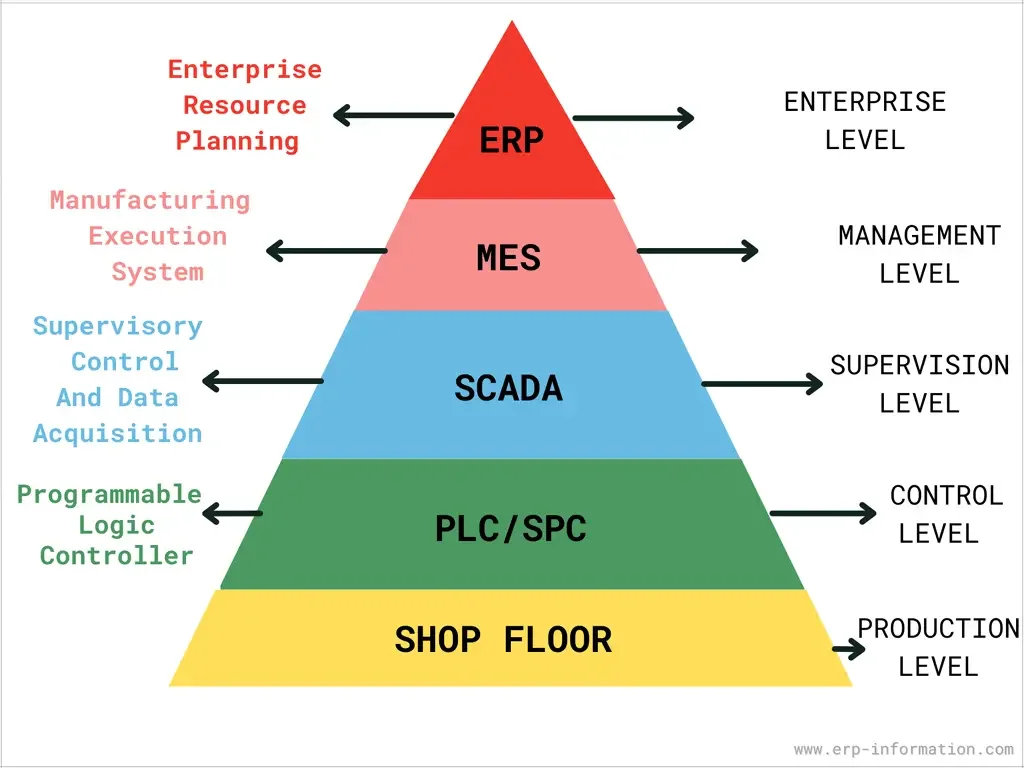

Enterprise Resource Planning (ERP) systems are essential for small manufacturers for a variety of reasons. These systems help streamline processes, improve efficiency, and increase overall productivity. By integrating various business functions such as accounting, inventory management, production planning, and customer relationship management into one cohesive system, ERP software provides small manufacturers with a centralized platform to manage all aspects of their operations.

One of the main benefits of using an ERP system for small manufacturers is the ability to automate repetitive tasks. This automation reduces the likelihood of human error and frees up employees to focus on more strategic tasks. With the help of ERP software, small manufacturers can improve their production planning processes, identify bottlenecks in their supply chain, and optimize their inventory levels to meet customer demand more effectively.

Another important aspect of ERP for small manufacturers is the ability to track and analyze data in real-time. By accessing up-to-date information on sales, production, and inventory levels, small manufacturers can make informed decisions quickly. This data visibility allows businesses to respond promptly to market changes, anticipate future demands, and adjust their strategies accordingly.

Furthermore, ERP systems provide small manufacturers with better visibility and control over their financials. By integrating accounting functions into the ERP platform, businesses can track expenses, manage cash flow, and generate accurate financial reports more efficiently. This transparency not only helps small manufacturers comply with regulatory requirements but also enables them to make data-driven decisions to improve their bottom line.

In addition to operational efficiency and financial control, ERP systems also play a crucial role in enhancing customer relationships for small manufacturers. By centralizing customer data and interaction history, businesses can provide personalized services, anticipate customer needs, and improve overall satisfaction. This customer-centric approach not only helps in retaining existing clients but also in attracting new business through positive referrals and word-of-mouth marketing.

Overall, the importance of ERP for small manufacturers cannot be overstated. These systems offer a comprehensive solution to streamline operations, optimize processes, and drive business growth. By investing in an ERP system, small manufacturers can stay competitive in today’s dynamic market and position themselves for long-term success.

Cost-effective ERP solutions for Small Manufacturers

Implementing an Enterprise Resource Planning (ERP) system can greatly benefit small manufacturers by streamlining processes, increasing efficiency, and improving overall business performance. However, cost can often be a barrier for smaller companies. Fortunately, there are cost-effective ERP solutions tailored specifically for small manufacturers that provide all the necessary tools without breaking the bank.

One option for small manufacturers looking for an affordable ERP solution is to opt for a cloud-based system. Cloud-based ERP systems offer several advantages, including lower upfront costs, easy scalability, and the ability to access the system from any device with an internet connection. This can be particularly beneficial for small manufacturers with limited resources, as they can avoid the high upfront costs associated with traditional on-premise ERP systems.

Another cost-effective ERP solution for small manufacturers is to choose a modular system. Instead of purchasing an all-in-one ERP system with features that may not be relevant to their specific needs, small manufacturers can select individual modules that are essential to their operations. This way, they can customize their ERP system to fit their budget and requirements, without paying for unnecessary features.

Open-source ERP systems are also a viable option for small manufacturers looking to cut costs. These systems are free to use and can be customized to meet the unique needs of the business. While open-source ERP systems may require more technical expertise to set up and maintain, they can be a cost-effective solution for small manufacturers willing to invest time and effort into the implementation process.

Lastly, small manufacturers can also consider partnering with an ERP provider that offers flexible pricing options. Some ERP vendors offer subscription-based pricing models, where companies pay a monthly fee based on the number of users or modules they require. This can be a cost-effective way for small manufacturers to access the benefits of an ERP system without committing to a large upfront investment.

In conclusion, cost-effective ERP solutions for small manufacturers are essential for improving efficiency, streamlining processes, and driving business growth. By choosing a cloud-based system, opting for modular features, exploring open-source options, or selecting a provider with flexible pricing models, small manufacturers can find the right ERP solution that meets their needs and budget.

Streamlining processes with ERP for Small Manufacturers

Implementing an Enterprise Resource Planning (ERP) system can greatly benefit small manufacturers by streamlining processes and increasing efficiency. By combining various functions such as production planning, inventory management, customer relationship management, and financials into a single integrated system, ERP can help small manufacturers eliminate redundancy, reduce errors, and improve overall productivity.

One of the key benefits of ERP for small manufacturers is the ability to centralize data and communication. Instead of relying on spreadsheets, emails, and manual processes, an ERP system allows all departments to access real-time information from a single source. This means that everyone in the organization is on the same page, reducing delays and ensuring accurate decision-making.

Another advantage of ERP is its automation capabilities. Small manufacturers can automate routine tasks such as order processing, invoicing, and reporting, freeing up employees to focus on more strategic activities. Automating these processes not only saves time but also reduces the risk of errors and ensures consistency in operations.

Additionally, ERP systems provide advanced reporting and analytics tools, allowing small manufacturers to gain valuable insights into their operations. By tracking key performance indicators (KPIs) and analyzing data, manufacturers can identify areas for improvement, optimize processes, and make data-driven decisions. This visibility into the business performance can help small manufacturers stay competitive in the market and adapt to changing market conditions.

Furthermore, ERP systems can help small manufacturers improve supply chain management by providing visibility into inventory levels, demand forecasting, and supplier performance. By optimizing supply chain processes, manufacturers can reduce lead times, minimize stockouts, and lower costs. This enhanced control over the supply chain not only improves operational efficiency but also enhances customer satisfaction by ensuring timely delivery of products.

In conclusion, implementing an ERP system can have a significant impact on small manufacturers by streamlining processes, increasing efficiency, and improving overall business performance. By centralizing data, automating tasks, and providing valuable insights, ERP systems enable manufacturers to make informed decisions, optimize operations, and stay competitive in the marketplace. With the benefits of ERP for small manufacturers becoming increasingly apparent, it is essential for businesses to consider adopting an ERP system to drive growth and success.

Improving efficiency and productivity with ERP for Small Manufacturers

Small manufacturers are always looking for ways to streamline their operations and improve their productivity. Implementing an ERP system can be a game-changer for these businesses, as it helps to automate processes, eliminate manual tasks, and provide real-time data insights. With the right ERP solution in place, small manufacturers can significantly enhance their efficiency and productivity in the following ways:

1. Streamlining production processes: ERP systems are designed to optimize production scheduling, resource allocation, and inventory management. By integrating all aspects of the manufacturing process into a single platform, small manufacturers can minimize downtime, reduce waste, and improve overall production efficiency. With a centralized system in place, employees can easily access critical information and collaborate effectively to meet production goals.

2. Improving decision-making: One of the key benefits of ERP for small manufacturers is the ability to make data-driven decisions. With real-time insights into key performance metrics, such as production costs, inventory levels, and sales trends, decision-makers can quickly identify areas for improvement and take proactive steps to address them. This proactive approach can lead to better decision-making, increased agility, and ultimately, improved business outcomes.

3. Enhancing inventory management: Inventory management is a critical aspect of small manufacturing operations, as it directly impacts production costs and customer satisfaction. ERP systems provide small manufacturers with visibility into inventory levels, demand forecasts, and supplier information, enabling them to optimize their stocking levels, reduce stockouts, and minimize carrying costs. By automating inventory management processes, small manufacturers can ensure that they have the right materials on hand at the right time, leading to improved production efficiency.

4. Increasing collaboration and communication: Effective communication and collaboration are essential for small manufacturers to operate efficiently. ERP systems offer features such as real-time messaging, document sharing, and task assignments, which facilitate seamless collaboration among employees, departments, and external partners. By enabling better communication and coordination, ERP systems help to eliminate silos, improve workflow efficiency, and enhance overall productivity.

Overall, implementing an ERP system can be a game-changer for small manufacturers looking to improve efficiency and productivity. By streamlining production processes, improving decision-making, enhancing inventory management, and increasing collaboration and communication, small manufacturers can achieve significant gains in operational efficiency and business performance. With the right ERP solution in place, small manufacturers can position themselves for growth and success in a competitive market.

Challenges and solutions of implementing ERP for Small Manufacturers

Implementing an Enterprise Resource Planning (ERP) system can be a daunting task for small manufacturers. They often face unique challenges that larger companies do not encounter. However, with careful planning and the right solutions, small manufacturers can successfully implement an ERP system to streamline their operations and improve efficiency.

1. Cost

One of the major challenges for small manufacturers when implementing an ERP system is the cost involved. ERP systems can be expensive to purchase and implement, especially for small businesses with limited budgets. However, there are solutions available to help mitigate the cost of implementing an ERP system, such as opting for cloud-based solutions or choosing a system that is tailored to meet the specific needs of small manufacturers.

2. Complexity

Another challenge that small manufacturers face when implementing an ERP system is the complexity of the software. ERP systems are often robust and feature-rich, which can make them difficult to implement and use, especially for small businesses with limited IT resources. To address this challenge, small manufacturers can opt for user-friendly ERP systems that are designed specifically for small businesses, or invest in training and support for their employees to help them navigate the software effectively.

3. Integration

Integrating an ERP system with existing software and systems can be a challenge for small manufacturers. Compatibility issues and data migration can cause disruptions to operations and lead to costly downtime. To overcome this challenge, small manufacturers can work with ERP vendors or consultants who specialize in integration to ensure a smooth transition and minimize the risk of data loss.

4. Resistance to change

Resistance to change is common among employees when implementing an ERP system. Many employees may be hesitant to adopt new technology and processes, which can hinder the success of the implementation. To address this challenge, small manufacturers can involve employees in the decision-making process, provide training and support, and communicate the benefits of the ERP system to help overcome resistance to change.

5. Scalability

One of the challenges small manufacturers face when implementing an ERP system is ensuring that the system is scalable to accommodate future growth. Small manufacturers may start with a limited number of users and modules, but as the business grows, they will need to expand the system to support additional users and functionality. To address this challenge, small manufacturers can choose an ERP system that is easily scalable and can grow with their business. They can also work with ERP vendors to develop a roadmap for future expansion and upgrades to ensure that the system can meet their evolving needs.